High Quality for Insulated Glaze Glass Production Line - IGL-2510E-SS Automatic insulated glass production line with sealing robot – CBS

High Quality for Insulated Glaze Glass Production Line - IGL-2510E-SS Automatic insulated glass production line with sealing robot – CBS Detail:

Features and functions:

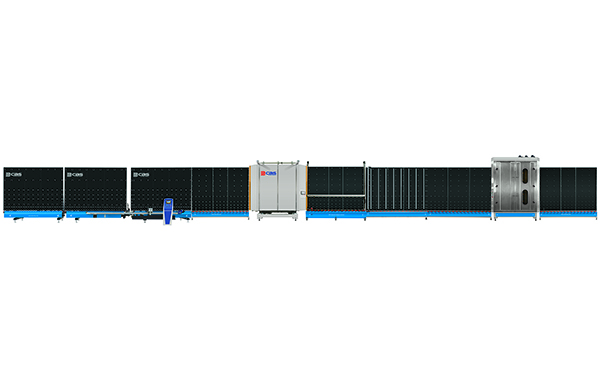

1. The production line including glass loading section, washing & drying section, glass transportation section, inspection & spacer assembly section, glass assembly section, plate press section, output section and sealing robot.

2. Automatically distinguish he coating side of coated glass and Low-E glass.

3. PLC controller with touch screen operation.

4. It adopts outside glass assembly, which can produce standard double layer IGU and three layers insulated glass unit.

5. Plate press section adopt gear and chain synchronous devise and driven by hydraulic station. The plate press table also openable for maintenance.

6. Whole line adopt frequency converter to adjust speed, output 800 PCS per shift.

7. Integrated with automatic sealing robot which increased the productivity. Double set sealing extruding system is optional.

8. Inside plate press is optional for step IGU production.

Technical parameter:

|

Processed I.G. unit size |

Min: 300x450mm, Max: 2500x3000mm, 2500x3500mm(over long unit, Optional) |

|

Ways of assembly |

Outside automatic assembly, inside plate press |

|

Power |

3-Phase, 4 wires, 380V 50Hz, 37kW |

|

Air consumption |

800L/min |

|

Washing speed |

2-8m/min |

|

Max. working speed |

45m/min(adjustable according to requirement) |

|

Single glass thickness: |

3-15 mm |

|

Insulating glass unit thickness |

12 ~ 50mm; |

|

Compressed air supply |

0.5-1.0Mpa, 0.8m3/min |

|

Water electrical conductivity |

≦50μS/cm |

|

Ambient temperature |

10℃-30℃, following DIN 40040 |

|

Relative air humidity |

≦75%, following DIN 40040 |

|

Overall dimension |

33750x2300x3400mm |

Product detail pictures:

Related Product Guide:

We have been ready to share our knowledge of advertising worldwide and recommend you suitable products at most aggressive costs. So Profi Tools present you ideal price of money and we've been ready to create with each other with High Quality for Insulated Glaze Glass Production Line - IGL-2510E-SS Automatic insulated glass production line with sealing robot – CBS , The product will supply to all over the world, such as: Vancouver , Leicester , South Korea , What is good price? We provide customers with factory price. In the premise of good quality, efficiency must be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products in time. Sincerely hope we could have long term business relationship.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.