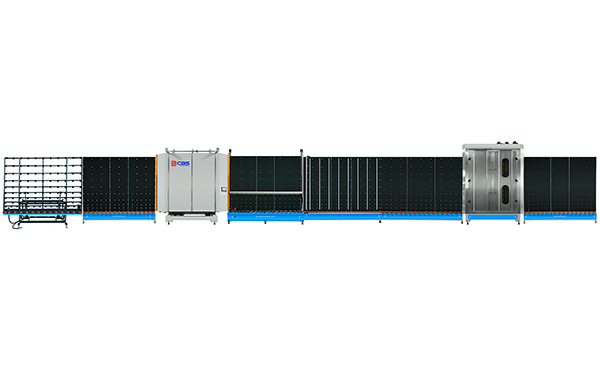

IGL-2508E Automatic Insulating Glass Production Line

Features and functions:

- The production line including glass loading section, washing & drying section, glass transportation section, inspection & spacer assembly section, glass assembly section, plate press section, output section and tilting table.

- Automatically distinguish he coating side of coated glass and Low-E glass.

- PLC controller with touch screen operation.

- It adopts outside glass assembly, which can produce standard double layer IGU and three layers insulated glass unit.

- Plate press section adopt gear and chain synchronous devise and driven by hydraulic station. The plate press table also openable for maintenance.

- Whole line adopt frequency converter to adjust speed, output 800 PCS per shift.

- Inside plate press is optional for step IGU production.

Technical parameter:

| Processed I.G. unit size | Min: 300x450mm, Max: 2500x3000mm, 2500x3500mm(over long unit, Optional) |

| Ways of assembly | Outside automatic assembly, inside plate press |

| Power | 3-Phase, 4 wires, 380V 50Hz, 27kW |

| Air consumption | 600L/min |

| Washing speed | 2-8m/min |

| Max. working speed | 45m/min(adjustable according to requirement) |

| Single glass thickness: | 3-15 mm |

| Insulating glass unit thickness | 12 ~ 50mm; |

| Compressed air supply | 0.5-1.0Mpa, 0.8m3/min |

| Water electrical conductivity | ≦50μS/cm |

| Ambient temperature | 10℃-30℃, following DIN 40040 |

| Relative air humidity | ≦75%,following DIN 40040 |

| Overall dimension | 26050x2300x3400mm |

- Previous :IGL-2510E-SD Automatic insulated glass production line with sealing robot

- Next:IGL-2208E Automatic Insulating Glass Production Line

Write your message here and send it to us