OEM Factory for China 20 Motors Glass Straight Line Double Edge/Edging Grinding and Polishing Processing Machine with Ce Certificate (Jfsz-4200)

Our well-equipped facilities and great good quality regulate throughout all stages of manufacturing enables us to guarantee total buyer gratification for OEM Factory for China 20 Motors Glass Straight Line Double Edge/Edging Grinding and Polishing Processing Machine with Ce Certificate (Jfsz-4200), When you’ve got any remarks about our firm or merchandise, please come to feel no cost to call us, your coming mail will likely be really appreciated.

Our well-equipped facilities and great good quality regulate throughout all stages of manufacturing enables us to guarantee total buyer gratification for China Glass Edging Machine, Glass Machinery, We’ve been very responsible for all details on our customers order no matter on warranty quality, satisfied prices, quick delivery, on time communication, satisfied packing, easy payment terms, best shipment terms, after sales service etc. We supply one-stop service and best reliability to our every customers. We work hard with our customers, colleagues, workers to make a better future.

Features and functions:

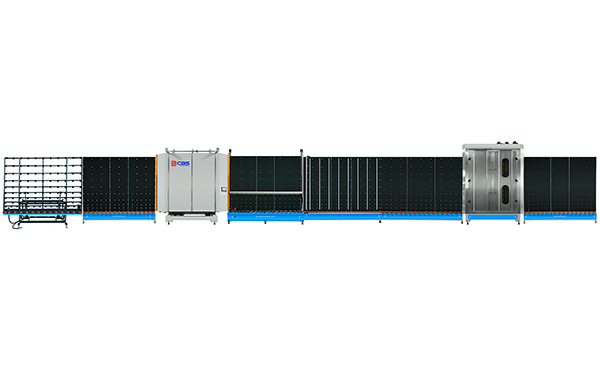

- The production line including glass loading section, washing & drying section, glass transportation section, inspection & spacer assembly section, glass assembly section, plate press section, output section and tilting table.

- Automatically distinguish he coating side of coated glass and Low-E glass.

- PLC controller with touch screen operation.

- It adopts outside glass assembly, which can produce standard double layer IGU and three layers insulated glass unit.

- Plate press section adopt gear and chain synchronous devise and driven by hydraulic station. The plate press table also openable for maintenance.

- Whole line adopt frequency converter to adjust speed, output 800 PCS per shift.

- Inside plate press is optional for step IGU production.

Technical parameter:

| Processed I.G. unit size | Min: 300x450mm, Max: 2500x3000mm, 2500x3500mm(over long unit, Optional) |

| Ways of assembly | Outside automatic assembly, inside plate press |

| Power | 3-Phase, 4 wires, 380V 50Hz, 27kW |

| Air consumption | 600L/min |

| Washing speed | 2-8m/min |

| Max. working speed | 45m/min(adjustable according to requirement) |

| Single glass thickness: | 3-15 mm |

| Insulating glass unit thickness | 12 ~ 50mm; |

| Compressed air supply | 0.5-1.0Mpa, 0.8m3/min |

| Water electrical conductivity | ≦50μS/cm |

| Ambient temperature | 10℃-30℃, following DIN 40040 |

| Relative air humidity | ≦75%,following DIN 40040 |

| Overall dimension | 26050x2300x3400mm |

- Previous :IGL-2510E-SD Automatic insulated glass production line with sealing robot

- Next:IGL-2208E Automatic Insulating Glass Production Line