OEM/ODM China China Supplied Exclusive Patent Tempered Glass Tile Processing Machine with Various 3D Pictures Design

Our eternal pursuits are the attitude of “regard the market, regard the custom, regard the science” as well as theory of “quality the basic, have faith in the initial and administration the advanced” for OEM/ODM China China Supplied Exclusive Patent Tempered Glass Tile Processing Machine with Various 3D Pictures Design, We’ve been also regularly wanting to establish relationship with new suppliers to supply ground breaking and intelligent option to our valued clients.

Our eternal pursuits are the attitude of “regard the market, regard the custom, regard the science” as well as theory of “quality the basic, have faith in the initial and administration the advanced” for China 3D Tile, Glass Tile, We’ve got won a good reputation among overseas and domestic clients. Adhering to the management tenet of “credit oriented, customer first, high efficiency and mature services”, we warmly welcome friends from all walks of life to cooperate with us.

Features and functions:

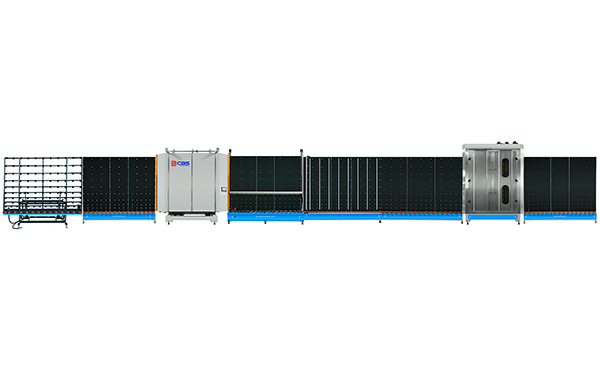

- The production line including glass loading section, washing & drying section, glass transportation section, inspection & spacer assembly section, glass assembly section, plate press section, output section and tilting table.

- Automatically distinguish he coating side of coated glass and Low-E glass.

- PLC controller with touch screen operation.

- It adopts outside glass assembly, which can produce standard double layer IGU and three layers insulated glass unit.

- Plate press section adopt gear and chain synchronous devise and driven by hydraulic station. The plate press table also openable for maintenance.

- Whole line adopt frequency converter to adjust speed, output 800 PCS per shift.

- Inside plate press is optional for step IGU production.

Technical parameter:

| Processed I.G. unit size | Min: 300x450mm, Max: 2500x3000mm, 2500x3500mm(over long unit, Optional) |

| Ways of assembly | Outside automatic assembly, inside plate press |

| Power | 3-Phase, 4 wires, 380V 50Hz, 27kW |

| Air consumption | 600L/min |

| Washing speed | 2-8m/min |

| Max. working speed | 45m/min(adjustable according to requirement) |

| Single glass thickness: | 3-15 mm |

| Insulating glass unit thickness | 12 ~ 50mm; |

| Compressed air supply | 0.5-1.0Mpa, 0.8m3/min |

| Water electrical conductivity | ≦50μS/cm |

| Ambient temperature | 10℃-30℃, following DIN 40040 |

| Relative air humidity | ≦75%,following DIN 40040 |

| Overall dimension | 26050x2300x3400mm |

- Previous :IGL-2510E-SD Automatic insulated glass production line with sealing robot

- Next:IGL-2208E Automatic Insulating Glass Production Line