Wholesale Price China TBR Full Convection System Low E Tempered Glass Processing Machine for Architectural Dynamic Glass Insulating Glass

We take pleasure in an exceptionally excellent status between our buyers for our superb merchandise good quality, aggressive price tag and the greatest support for Wholesale Price China TBR Full Convection System Low E Tempered Glass Processing Machine for Architectural Dynamic Glass Insulating Glass, In addition, we would properly tutorial the purchasers about the application techniques to adopt our items plus the way to select appropriate materials.

We take pleasure in an exceptionally excellent status between our buyers for our superb merchandise good quality, aggressive price tag and the greatest support for China Glass Furnace, Low-E Glass Tempering Furnace, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.

Features and functions:

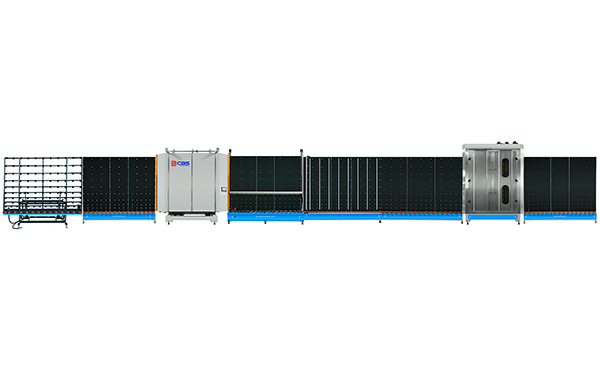

- The production line including glass loading section, washing & drying section, glass transportation section, inspection & spacer assembly section, glass assembly section, plate press section, output section and tilting table.

- Automatically distinguish he coating side of coated glass and Low-E glass.

- PLC controller with touch screen operation.

- It adopts outside glass assembly, which can produce standard double layer IGU and three layers insulated glass unit.

- Plate press section adopt gear and chain synchronous devise and driven by hydraulic station. The plate press table also openable for maintenance.

- Whole line adopt frequency converter to adjust speed, output 800 PCS per shift.

- Inside plate press is optional for step IGU production.

Technical parameter:

| Processed I.G. unit size | Min: 300x450mm, Max: 2500x3000mm, 2500x3500mm(over long unit, Optional) |

| Ways of assembly | Outside automatic assembly, inside plate press |

| Power | 3-Phase, 4 wires, 380V 50Hz, 27kW |

| Air consumption | 600L/min |

| Washing speed | 2-8m/min |

| Max. working speed | 45m/min(adjustable according to requirement) |

| Single glass thickness: | 3-15 mm |

| Insulating glass unit thickness | 12 ~ 50mm; |

| Compressed air supply | 0.5-1.0Mpa, 0.8m3/min |

| Water electrical conductivity | ≦50μS/cm |

| Ambient temperature | 10℃-30℃, following DIN 40040 |

| Relative air humidity | ≦75%,following DIN 40040 |

| Overall dimension | 26050x2300x3400mm |

- Previous :IGL-2510E-SD Automatic insulated glass production line with sealing robot

- Next:IGL-2208E Automatic Insulating Glass Production Line